Our Premier Aluminum Llc Diaries

Our Premier Aluminum Llc Diaries

Blog Article

Our Premier Aluminum Llc Ideas

Table of ContentsNot known Facts About Premier Aluminum LlcAn Unbiased View of Premier Aluminum LlcFacts About Premier Aluminum Llc UncoveredPremier Aluminum Llc - The Facts

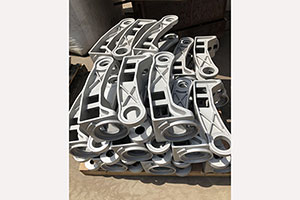

(https://premieraluminum.wordpress.com/2024/12/12/premier-aluminum-llc-your-trusted-aluminum-casting-company/)Commonly, a buyer's primary responsibility was to find competent and receptive vendors. Sometimes, buyers thought that any kind of distributor ready to contractually satisfy the acquisition need was certified. Nonetheless, making use of inexpensive and unqualified distributors can cause quality problems, and squandered time and money in the lengthy run. To help you via the process, below are some points to think about when picking the best steel spreading vendor.

A company that only makes use of the investment spreading procedure will attempt to offer you on why that procedure is best for your application (Foundry). What if using the sand spreading process is best for you and your requirements? Instead, look for a vendor that supplies a series of casting procedures so the very best alternative for YOU is selected

If working with a single source for every one of your casting requires is important to you, the distributor requires to be diverse in its capabilities. When combined with various other integrated abilities, this can assist streamline and compress the supply base. When choosing the best casting supplier, cautious consideration ought to be provided to top quality, solution, and price.

Premier Aluminum Llc Things To Know Before You Buy

Buyers significantly select spreading distributors that have machining capabilities. This can prevent problem if issues are found throughout machining. If a third party is machining, it may lead to "finger-pointing" about who is at fault. Is it advice a spreading issue or a machining issue? If the casting vendor discovers a problem throughout machining, the problem is resolved quicker without conflict over whose fault it is.

What do you need from your spreading distributor? Are you looking for a person to just supply a steel element to your front door or do you need extra?

Some factories are limited or specialized. Make sure the provider can fulfill all your material or alloy demands to eliminate the demand for multiple providers.

Not known Factual Statements About Premier Aluminum Llc

Research the supplier's website. Talk to a sales representative or business associate.

Aluminum is likewise lightweight and has great deterioration resistance, making it optimal for applications where weight and sturdiness are necessary factors. Furthermore, light weight aluminum spreading is an economical technique of production, as it needs less power and sources than other techniques. Iron spreading, on the various other hand, includes pouring liquified iron right into a mold and mildew to create a preferred form.

A Biased View of Premier Aluminum Llc

Iron casting is likewise able to stand up to high temperature levels, making it appropriate for usage in applications such as engine parts and industrial equipment. Iron spreading can be a lot more expensive than aluminum casting due to the greater expense of raw products and the power called for to melt the iron. When choosing between light weight aluminum casting and iron spreading, it is vital to think about the specific needs of the application.

In verdict, both light weight aluminum spreading and iron casting have their very own one-of-a-kind advantages and drawbacks. There are 3 sub-processes that fall under the group of die spreading: gravity pass away spreading (or irreversible mold casting), low-pressure die spreading and high-pressure die spreading. To get to the ended up item, there are three main alloys utilized as die casting material to select from: zinc, light weight aluminum and magnesium. Report this page